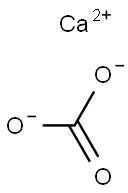

A common calcium source (CaCO₃, 40% elemental calcium), used in supplements and antacids. Particle size impacts solubility: nanoparticulate forms improve absorption, while micronized versions aid stomach acid neutralization in antacids

| Calcium Carbonate Particles |  |

| CAS | 471-34-1 |

| molecular weight | 100.0869 |

| molecular formula | CCaO3 |

| solubility | MHCl:0.1 Mat 20℃, transparent, colorless |

| color | White beige to light beige |

| flavor | Odorless |

| state | Crystals |

| melting point | 825℃ |

| boiling point | 800℃ |

alcium carbonate particles, available in various sizes (from micron to nanoscale) and forms, offer a range of benefits across industries, from healthcare to manufacturing. Here’s a breakdown of their key advantages:

1. High Calcium Content for Nutritional & Pharmaceutical Use

Premium Calcium Supplement: As a primary ingredient in dietary calcium supplements, calcium carbonate particles provide the highest elemental calcium content (40% by weight), making them an efficient choice for addressing calcium deficiencies. This is critical for bone health, muscle function, and nerve transmission, especially for populations at risk of osteoporosis (e.g., postmenopausal women, older adults).

Antacid Action: In medicinal formulations, fine calcium carbonate particles neutralize excess stomach acid, relieving heartburn, indigestion, and acid reflux. Their large surface area (in micronized form) ensures rapid reaction with gastric acid for fast-acting relief.

2. Versatile Industrial Filler & Reinforcing Agent

Enhanced Material Properties: In plastics, rubber, and polymers, calcium carbonate particles act as fillers to improve mechanical properties (e.g., tensile strength, hardness, impact resistance) while reducing production costs. Their inert nature ensures compatibility with most matrices, making them ideal for products like pipes, automotive parts, and packaging.

Texture & Stability in Coatings/Adhesives: In paints, coatings, and adhesives, these particles enhance opacity, thickness, and surface smoothness. They also improve resistance to weathering and UV degradation, extending the lifespan of industrial and decorative finishes.

3. Controlled Particle Size for Targeted Applications

Nanoscale Particles for Advanced Uses: Nano-calcium carbonate offers unique properties, such as increased surface area and reactivity, making it valuable in:

Drug Delivery Systems: Encapsulating medications for targeted release or enhanced bioavailability.

Cosmetics: As an additive in sunscreens (UV scattering) or creams (texture improvement), with nano-sized particles ensuring seamless application without chalkiness.

Micronized Particles for Food & Agriculture: In food products, micronized calcium carbonate serves as a fortifier (e.g., in flours, juices) and anti-caking agent. In agriculture, it adjusts soil pH and provides calcium to plants, improving crop health and yield.

4. Environmental & Sustainability Benefits

Carbon Capture & Storage (CCS): Calcium carbonate particles are used in industrial processes to absorb CO₂, such as in flue gas desulfurization (FGD) systems to reduce sulfur emissions from power plants. They also play a role in mineral carbonation, a method to permanently store CO₂ as stable carbonates.

Biodegradable Composite Support: In eco-friendly materials, calcium carbonate fillers enhance the biodegradability of plastics by promoting fragmentation and microbial assimilation, reducing environmental waste.

5. Cost-Effective & Abundant Natural Resource

Economical Production: Derived from limestone, marble, or chalk—abundant natural sources—calcium carbonate particles are cost-effective to mine, process, and modify for various applications. This affordability makes them a preferred choice across industries, from low-cost supplements to high-volume industrial materials.

Regulatory Safety: Widely recognized as safe (GRAS) by regulatory bodies (e.g., FDA, EFSA) for use in food, pharmaceuticals, and consumer products, ensuring compliance and consumer trust.

6. Precision in Medical & Dental Applications

Bone Graft Substitutes: In orthopedics, porous calcium carbonate particles (e.g., synthetic coral-like structures) act as scaffolds for new bone tissue growth, promoting osseointegration in joint replacements or spinal fusion surgeries.

Dental Fillings & Whitening: Fine particles are used in toothpaste as an abrasive to remove stains gently while providing calcium to remineralize enamel, supporting oral health.

Calcium carbonate particles stand out for their adaptability, combining high calcium potency in healthcare with mechanical and functional enhancements in industry, all while offering environmental and cost advantages. Their versatility across scales and sectors makes them an indispensable ingredient in modern manufacturing and wellness.

Dense Calcium Source: With the highest elemental calcium content of any supplement (40% by weight), calcium carbonate particles deliver a concentrated dose of this essential mineral. This makes them ideal for fortifying foods to meet daily recommended intakes (e.g., 1,000–1,300 mg/day for adults), especially for populations at risk of deficiency—such as vegetarians, older adults, or those with limited dairy intake.

Acid-Activated Absorption: In the stomach, calcium carbonate reacts with gastric acid to release ionic calcium, which is readily absorbed in the intestines. While its absorption efficiency is slightly lower than organic calcium forms (e.g., citrate), its sheer calcium density makes it a cost-effective choice for large-scale fortification, ensuring meaningful calcium delivery when paired with vitamin D (which enhances uptake).

Dual Role as Nutrient and Processing Aid: Beyond fortification, calcium carbonate particles serve practical functions in food formulation:

Anti-Caking Agent: In powdered foods (e.g., infant formula, seasoning blends), fine-grade particles prevent clumping, ensuring uniform texture and easy dispersion.

pH Regulator: In beverages (e.g., plant-based milks, juices) and processed meats, they stabilize acidity, improving shelf-life and flavor consistency.

Texture Enhancer: In baked goods (e.g., bread, pastries), they act as a mineral salt to strengthen gluten structure, enhancing crumb texture and shelf stability.

Versatile Application Across Categories: From fortifying breakfast cereals, oatmeal, and nutrition bars to enriching plant-based milks, juices, and even confectionery (e.g., calcium-fortified chocolates), calcium carbonate integrates seamlessly without altering taste or appearance, making nutrient enhancement accessible in everyday foods.

GRAS-Approved and Widely Regulated: Recognized as Generally Recognized As Safe (GRAS) by the FDA and approved by global food safety authorities (e.g., EFSA, Codex Alimentarius), calcium carbonate is a trusted ingredient for both infant nutrition and adult food products. Its long history of use in food fortification minimizes regulatory hurdles for manufacturers.

Natural and Accessible Source: Derived from abundant natural minerals (limestone, chalk, marble), calcium carbonate particles are eco-friendly and cost-effective, aligning with consumer preferences for clean, natural ingredients. This sustainability factor, combined with its role in preventing calcium-related health issues (e.g., rickets, osteoporosis), positions it as a responsible choice for public health initiatives.

Tailored Fortification for Specific Needs:

Pediatric Formulations: In toddler foods and school snacks, calcium carbonate ensures growing children receive adequate calcium for bone and teeth development, a critical nutrient often underconsumed in modern diets.

Senior Nutrition: In fortified ready-to-eat meals or supplements for older adults, its high calcium load supports bone density maintenance, a key concern as age-related absorption declines.

Plant-Based Diets: As dairy alternatives gain popularity, fortifying almond milk, soy yogurt, and vegan cheeses with calcium carbonate bridges the nutrient gap, ensuring non-dairy eaters meet calcium requirements.

By combining potent calcium delivery with functional food-processing benefits, calcium carbonate particles serve as a pragmatic, safe, and effective solution for global food fortification efforts. They exemplify how a single ingredient can address both nutritional deficiencies and formulation needs, making nutrient-rich foods accessible, affordable, and appealing to diverse consumers.